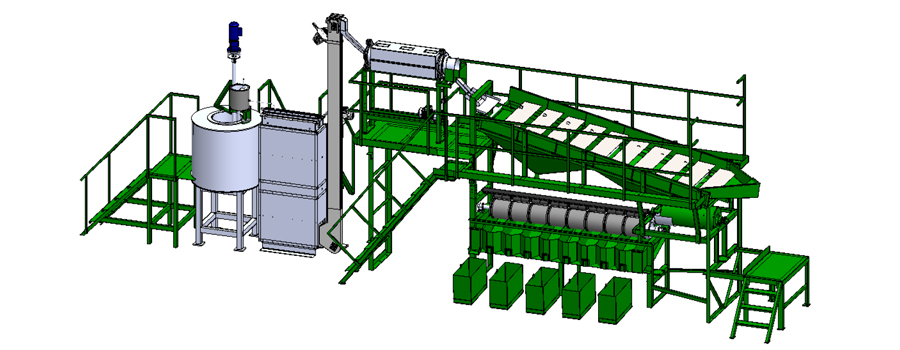

LEAD SHOT MACHINE

LEADSHOT PRODUCTION LINE The machine needds 57 kW electricity. Also 6 bar pressure air is needed. Has a capacity to produce 350 kg. leadshot per hour in average. Produces leadshot starting from 1,90mm. to 3,75mm.1-MELTING POT: Melting pot is equiped with a mixer and a special pump. The capacity is 3 ton and suaitable for continues feeding. The melting pot can be used by electricity or gas depending on customer’s preferance

2-CASTING TANK: The melted lead is fed ito the molding system. The mold has a 5 layer structure. With a special molding heat, layer selection, water heat and plate angle the system produces the needed leadshot size. Every parameter is controlled by sensors.

3- ELEVATOR: An elavator takes the casted leadshot into the drying drum.

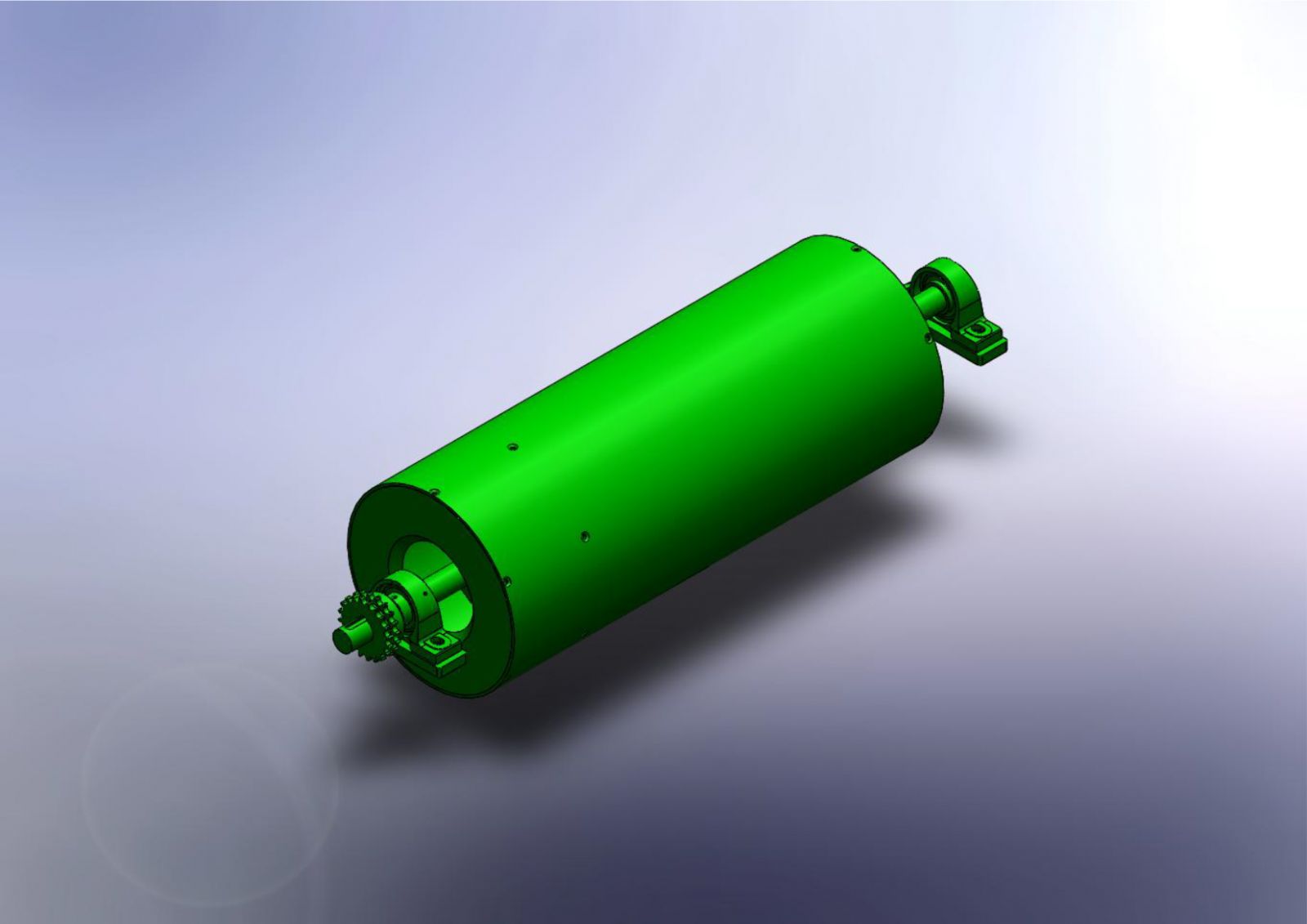

4-DRYER: The wet leadshot getting dried in a speacial dryer drum. Exit side of the dryer a very first non-shperic leadshot elimination system is placed.

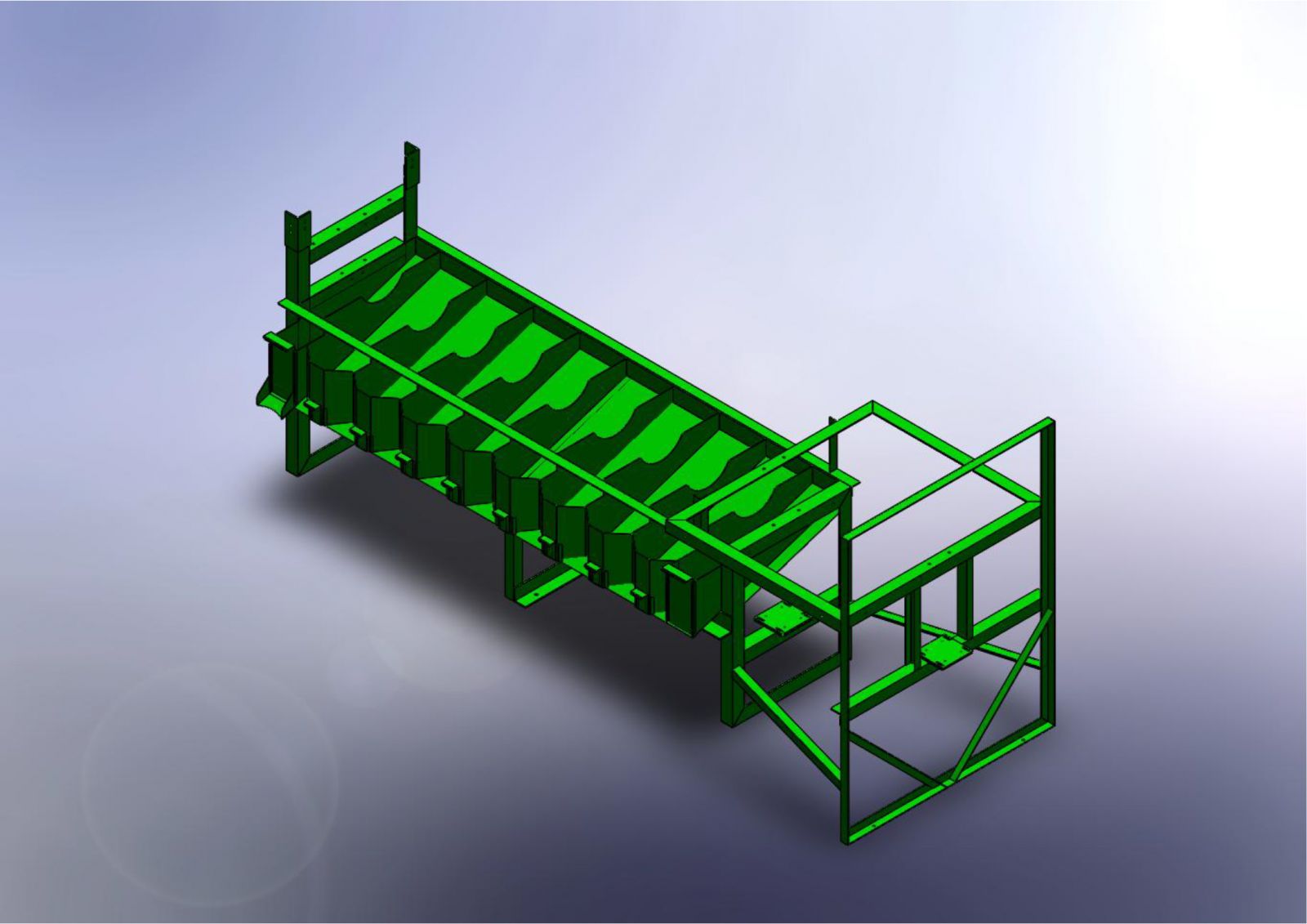

5- MIRROR: 10 layer mirror eliminates all non spheric leadshot. The sensitivity of the eliminaton is also adjustable.

6- GRAPHITE COATING: The eliminated leadshots g oto graphite coating drum. It protects the leadshot and gives a shiny effect.

7- CALIBRATION: With a special drum with different diameter wholes on it the graphite coated leadshots are calibrated and selected. Now we have different size of leadshots grouped.

8- UNLOADING SECTION: All selected and calibrated leadshots are stocked in special cases. Here if the quality approved by the operator it is fed into delivery cars.

Data: 09 May2018